FORMADRAIN HELPS FOOD INDUSTRY COMPANY AVOID PRODUCTION DOWNTIMES AND COSTLY EXCAVATION

The speed, durability, and versatility of FORMADRAIN’s Formapox 301 industrial trenchless liners recently saved one of our customers from shutting down their entire production plant and having to pay for expensive excavation to get to the bottom of—and resolve—the reason why the floor drains kept backing up. Let’s dive into how FORMADRAIN got the job done.

Our customer, a company in the Canadian food industry, came to us after nearly nine months of struggling with floor drains that were constantly clogging, compromising operational efficiency and compliance with the sector’s strict hygiene standards.

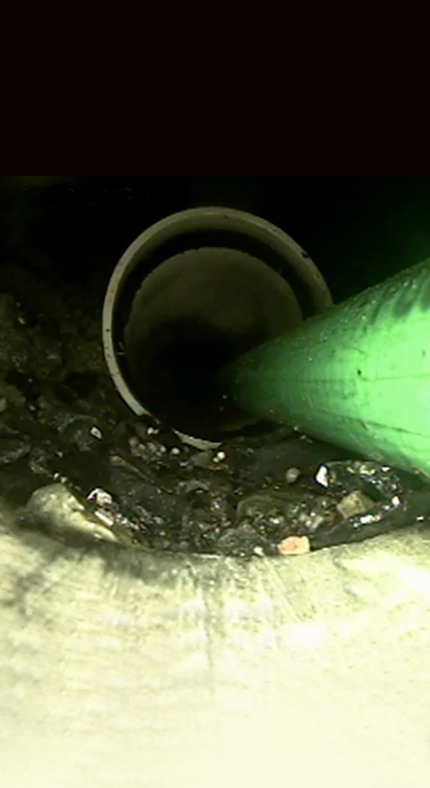

Thanks to a CCTV inspection, the customer was able to identify that about 100 ft. of the underground piping network, which was made out of PVC, was being impacted by the exceedingly hot water and liquid waste being discharged by the production line. Due to the use of very hot water, the plastic pipes went through multiple cycles of deformation and as a result, fittings became disconnected, causing wide openings. The advanced and excessive damage to the drainage system, which could have collapsed at any moment, had a loss of fill in several places.

The facility, unfortunately, was not necessarily originally built with the right sanitary drains that could withstand the extremely hot water and chemicals that food processing businesses emit.

The main problem was that the piping network ran under the entire production line. Fixing the damaged pipes with traditional means would have meant shutting down production, moving the equipment, and, of course, digging. The entire operation would have taken months, costing the customer a lot of money—both for the repairs and in lost sales.

The FORMADRAIN team knew there was a better way.

The production line was stopped on Mondays for maintenance. With the customer, we planned to use our trenchless liners to fix the issue over four consecutive Mondays, which meant no forced shutdowns.

We opted for FORMADRAIN’s Formapox 301 heavy-duty liners, designed specifically for extreme industrial conditions and certified ICC-ES (PMG-1203). We worked in sections because the under-slab network was complex, with many openings in the pipes and disconnections we needed to cap. We had little room for error in the measurements to bridge the piping back together so as not to create another set of problems with the drainage.

The results? Within weeks, the problem was solved without any excavation, the mess digging would have caused in a food-grade facility, and production interruptions. The customer was above all thrilled to notice that the floor drains didn’t clog anymore. “For all of our customers, whether or not they are in the food sector, we always recommend that inspections of floor drains and drainage systems be a part of a company’s overall regular maintenance plan,” said Carl Marc-Aurèle, Vice President at FORMADRAIN. “Regular maintenance can help to avoid nasty surprises and unplanned expenses. What’s more, proper maintenance extends the lifespan of drainage systems and reduces your CAPEX in the short and medium term.”

Do you want to offer your customers a no-dig solution?

Become a Formadrain installer

1-888-337-6764