The FORMADRAIN Solution to Orangeburg Pipe: Miracles Do Happen

Any plumber who has had experience with Orangeburg pipe is very familiar with its shortcomings. Orangeburg pipe, also called “black pipe”, “no-corrode pipe”, and “Bermico”, is bituminous fiber pipe made of layers of wood pulp impregnated with coal tar. Some plumbers refer to Orangeburg pipe as “coal-tar impregnated toilet paper tubes”.

It was used extensively in residential construction during the World War II years due to shortages of cast iron needed for the war effort. It continued to be used long after the war ended because it was inexpensive. Additionally, it was lightweight and could be cut with a saw, so it was easy to install.

The Problem

Orangeburg pipe had a life expectancy of 30-50 years, although there have been numerous cases of failure in as little as ten years. The manufacturer’s ads claimed that it was “root-proof”, but this has not always been the case. Widespread failure started in the 1990’s. The pipes began to flatten into ovals, the walls of the pipe started to sag and become soggy, the layers started to delaminate, and the pipes became highly susceptible to tree root intrusion. Efforts to mechanically clear out the roots caused further damage and degradation to the pipes.

The multiple failures of laterals made of Orangeburg pipe precipitated what has come to be known as “the Orangeburg crisis”, where thousands of homeowners had to contend with the effects of these failures such as slow draining, frequent toilet backups, foul sewer odours in the home, and sinkholes in the foundation of the house.

Some homeowners have not yet experienced Orangeburg pipe failure, but it is just a matter of time before they do. The question is not whether the pipe will fail; the question is when.

The problem has been so widespread that there are a number of municipalities who have banned the use of these types of pipes and some who have also enacted bylaws that require that any Orangeburg pipe detected must be immediately replaced.

The Solution

One approach to a failed Orangeburg pipe is to dig it up and replace it with a more robust metal, HDPE or PVC pipe. While this is sometimes the only option, as in the case of a lateral that has collapsed, the drawbacks to open-cut trenching are obvious. Excavation is time-consuming, destructive of landscaping and hardscaping, noisy, uses an excess of energy, and creates harmful environmental impacts such as air-borne dust and pollutants.

For many homeowners, a cost-effective, time-efficient, and environmentally friendly alternative is CIPP. FORMADRAIN is the no-dig pipe system that has successfully lined many hundreds of miles of pipe including Orangeburg pipe.

FORMADRAIN is a true no-dig technology. It is a steam-cured, fiberglass and epoxy system that is pulled-in-place or pushed-in-place through existing pipes. It is routinely used to repair laterals and other underground pipes without excavation. FORMADRAIN is used for lateral repairs, Lateral-Main-Connection® repairs, and spot repairs.

Steam curing ensures a controlled and complete cure of the liner and allows for year-round installation regardless of the ambient temperature.

Many 4-to-6-inch (100-150 mm) transitions are found in house laterals. Because FORMADRAIN liners are not tubes, they easily transition up to a 2-inch (50 mm) difference in diameter for seamless lining without the need for precision measuring and stitching.

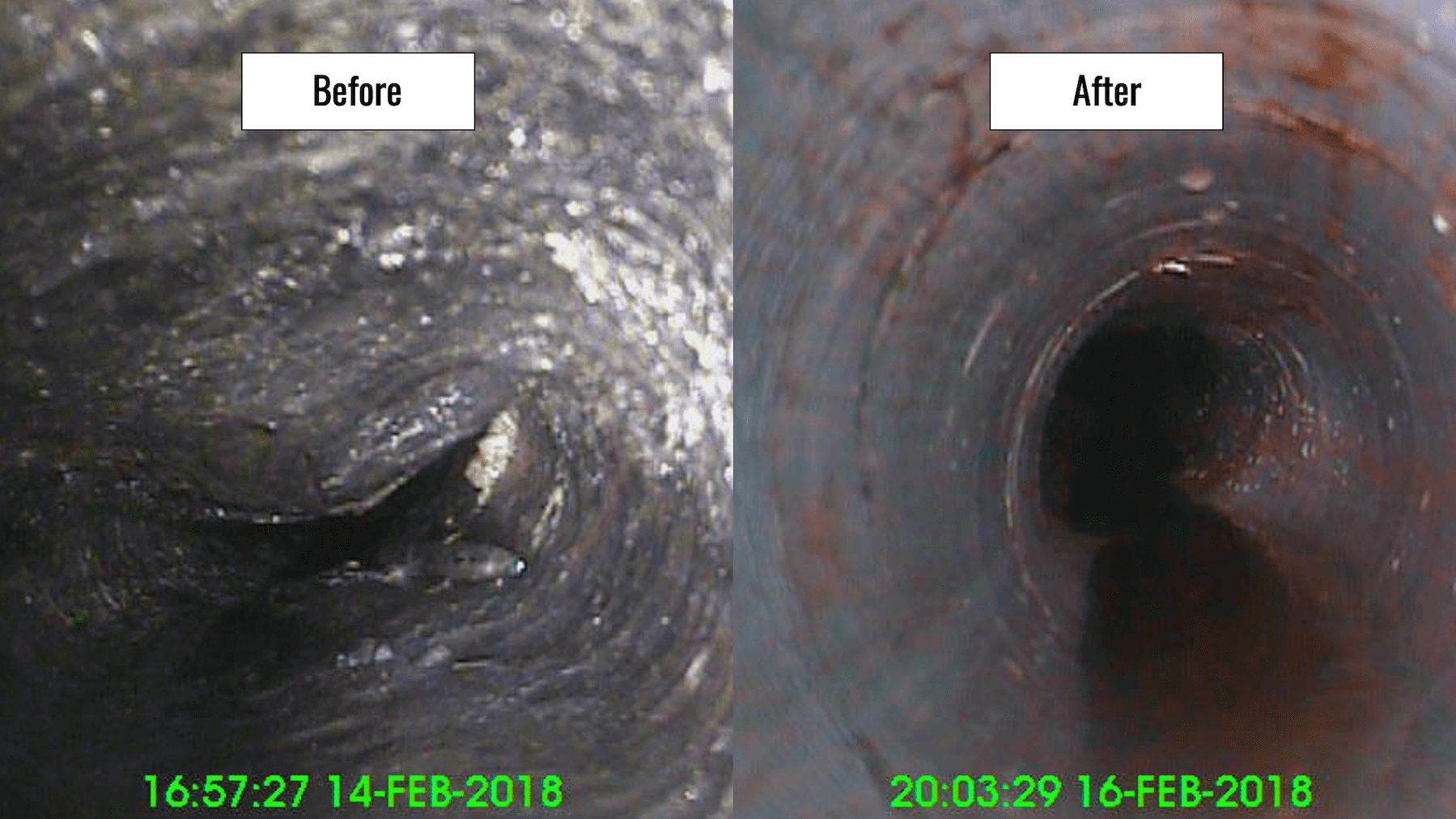

What is even better, the heat and the pressure applied during the steam curing will re-shape a deformed Orangeburg pipe to a perfectly round shape. Every Orangeburg pipe rehabilitated with FORMADRAIN is a small miracle.

FORMADRAIN liners are robust and durable. 13,000-hour tests of FORMADRAIN liners performed by CATT confirm the long term (50 years) Modulus of Flexural Elasticity of FORMADRAIN liners. FORMADRAIN liners exceeding the minimum ASTM F1216 standard by five times. They are NSF 14 certified and ICC-ES certified (PMG-1203).

FORMADRAIN is an environmentally sound alternative. The proprietary epoxy resins contain no VOCs. Liner installation takes a fraction of the time, does not damage pavement or landscape, does not create dust, and uses minimal fuel. It is also a cost-effective solution. The no-dig FORMADRAIN system uses the existing host pipe so the significant direct and indirect costs of open-cut trenching do not apply to the FORMADRAIN system.

For more information about FORMADRAIN’s no-dig lining solutions, call Bruce Stevenson, Business Development Manager, at 1-888-450-3986 or email Bruce@formadrain.com for your free info pack.